CNC MAchining Capabilities

Expert CNC Services for Complex Turned Parts

Interested in learning more about Our capabilities?

Services Overview

CES Machine specializes in complex, small-diameter turned components manufactured for regulated, high-reliability OEMs.

Our capabilities are intentionally focused on parts where precision, repeatability, documentation, and scale are mandatory, not optional.

We do not try to machine everything. We focus on what we do best: tight-tolerance turned parts under 3.00 inches diameter, produced under ISO 13485 and AS9100 discipline, from NPI through 100,000+ units annually.

Our shop includes 18 CNC machines with 13 Swiss screw and 5 lathes, featuring a mix of Tornos Decos machines and two newly added Tsugami Swiss-style machines. With financial and physical capacity to expand, our facility is poised for growth, with long-term goals of increasing capacity.

Our team includes engineering specialists, quality assurance professionals, and material management experts who collaborate to ensure every part meets exact specifications. With dedicated customer account managers, we provide a seamless experience from the initial quote to the delivery of completed components.

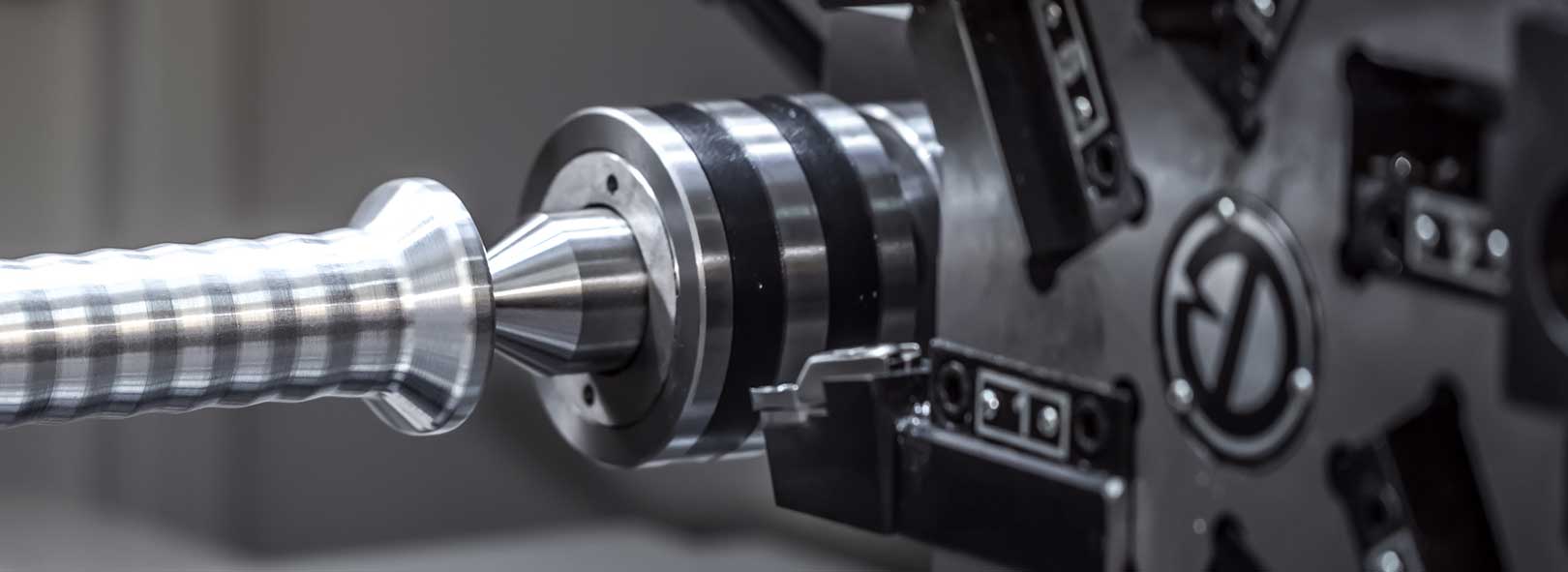

Swiss Screw Machining

Our Swiss screw machining services leverage the exceptional precision, repeatability, and efficiency of our Tornos Deco and Tsugami Swiss-style machines, positioning us as a trusted partner for high-precision Swiss screw machining. With 13 CNC Swiss machining centers and square footage to expand to 35 machines, our shop is built to support complex, tight-tolerance components that demand consistent accuracy, even across intricate geometries and challenging materials.

Our Swiss-type turning capability is purpose-built for complex geometries, tight concentricity, and superior surface finishes on small-diameter components.

Typical Swiss-turned work includes:

- Multi-feature shafts and sleeves

- Thin-wall and tight-runout components

- Precision interfaces and couplers

- Parts requiring simultaneous turning, milling, and cross-drilling

This capability is ideal for medical devices, robotics, aerospace mechanisms, and electromechanical assemblies where consistency matters more than speed alone.

Our Swiss machines feature programmable axes for 3D contoured features, live tooling, and sub-spindles, allowing multiple operations to be performed simultaneously. This capability reduces cycle times, minimizes secondary operations, and delivers exceptional dimensional control.

Our CNC Swiss equipment supports parts up to 1-1/2″ in diameter and 10″ in length, enabling us to efficiently produce both small, intricate components and more complex turned parts. With the ability to support high-mix, high-volume production, we manage programs from prototype through full production with consistency and scalability.

Backed by experienced machinists, rigorous quality standards, and lean manufacturing practices, we ensure every project is delivered with precision, efficiency, and dependable on-time performance meeting exact specifications while maintaining efficiency at scale.

Lathe Machining Services

Our CNC lathe services deliver reliable, high-precision turning solutions for a wide range of part sizes, materials, and production requirements. Our shop is equipped with five CNC lathe machining centers capable of handling bar stock up to 2-5/8″ in diameter, chucking diameters up to 12″, and parts up to 4 feet in length, allowing us to support both small, intricate components and larger turned parts.

These CNC lathes feature live tooling and sub-spindles, enabling complex geometries and secondary features such as cross-holes, flats, and milled profiles to be completed in fewer setups. This integrated approach improves dimensional accuracy, shortens cycle times, and reduces overall production costs while maintaining tight tolerances and consistent surface finishes.

Ideal for industries including aerospace, medical, defense, and industrial manufacturing, our CNC lathe capabilities support everything from short-run prototypes to repeat and higher-volume production. Backed by experienced machinists, disciplined process controls, and strict quality standards, we deliver precision-machined components with dependable consistency, efficiency, and on-time performance.

Finishing & Outside Processing

Beyond CNC machining, CES offers a comprehensive range of finishing and assembly services to ensure your components are fully production ready. These secondary processes allow us to deliver ready-to-use parts and assemblies, helping streamline your supply chain, reduce lead times, and simplify vendor management.

Our mechanical finishing services, including tumbling and deburring, improve surface quality, remove sharp edges, and ensure consistent, precise finishes that meet functional and aesthetic requirements. These processes enhance part performance while maintaining tight dimensional control.

CES also provides electro-mechanical turnkey assembly, offering end-to-end support for complex components and subassemblies. From individual machined parts to fully assembled systems, we manage the process to ensure proper fit, function, and quality reducing handling, coordination, and time to delivery.

In addition to in-house services, we coordinate a wide range of outside processing through trusted partners to meet specialized requirements. These capabilities include heat treating, anodizing, plating, passivation, electropolishing, non-destructive testing, honing, zinc finishing, and grinding. By managing these processes on your behalf, we ensure consistent quality, documentation, and on-time delivery while providing a single, reliable point of contact.

Materials

We work with a wide range of materials to suit your project's unique requirements, from durable metals to versatile plastics. Our expertise spans precision turning for aluminum parts, stainless steel parts, carbon steel, titanium, and more.

Below is a detailed overview of the materials we use, but not limited to:

- Carbon Steel: 1018, 12L14, 1144

- Alloy Steel: 4130, 4140, 8620

- Stainless Steel: 15-5, 17-4, 303, 304, 316, 416, 440C

- Aluminum: 2011, 2024, 6061, 7075

- Brass: 360, 385, 693

- Copper: 101, 110

- Titanium: 6Al-4V

- Plastics: Peek, Delrin, Acetal, Nylon

Built on Quality, Transparency, and Trust

ISO 9001, AS9100, and ISO 13485 certified and ITAR registered, supporting long-term programs in regulated industries with consistent quality, traceability, and dependable performance.

Request a Quote

Submit your RFQ to connect with our team, review your requirements, and receive competitive pricing supported by precision and reliable manufacturing.

Complete the form below or email your request to rfq@cesmachine.com.