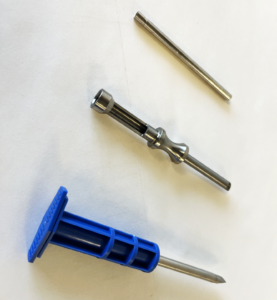

Medical Trocar Parts

Custom Medical Trocar Parts Manufacturing: Precision Solutions for Medical Device Manufacturers

In the medical industry, precision and reliability are paramount—especially when it comes to surgical instruments like medical trocar parts. These critical components, used in minimally invasive procedures, must meet exacting specifications to ensure patient safety and optimal performance. At CES Machine, we specialize in customized trocar manufacturing, leveraging our ISO 13485-certified processes and precision CNC Swiss machining capabilities to meet the unique needs of medical device manufacturers.

Why Customization Matters in Trocar Manufacturing

Trocar components are not one-size-fits-all. Medical device companies require specialized features and designs to align with surgical applications, regulatory requirements, and evolving industry innovations. Whether you need specific tip geometries, unique cannula lengths, or specialized coatings, CES Machine provides tailored solutions to optimize performance and manufacturing efficiency.

Key Customization Capabilities

At CES, we partner with medical device manufacturers to produce trocar components with:

- Precision Tip Geometry – From pyramidal to conical tips, we customize the design for optimal penetration and reduced patient trauma.

- Custom Cannula Sizes – We machine trocars in various lengths and diameters to accommodate different surgical applications.

- Advanced Material Expertise – Our team works with biocompatible materials such as stainless steel, titanium, and medical-grade polymers, ensuring durability and corrosion resistance.

- Surface Finishing & Coatings – We offer polishing, passivation, and specialty coatings to enhance lubricity, reduce friction, and improve performance in surgical procedures.

- Full Traceability & Compliance – Every component is manufactured under ISO 13485-certified quality control processes, ensuring complete traceability and compliance with FDA and EU MDR regulations.

High-Precision CNC Swiss Machining for Medical Components

Our CNC Swiss machining technology allows us to manufacture complex trocar components with micron-level precision. This advanced machining process enables:

- Tight Tolerances – We achieve extremely fine tolerances to meet the exact requirements of surgical applications.

- High-Volume Production – Our automated Swiss machining capabilities allow for cost-efficient, repeatable production at scale.

- Consistent Quality Control – Each part undergoes rigorous inspection to ensure it meets medical-grade safety and performance standards.

Partner with CES Machine for Your Custom Trocar Needs

With decades of experience in medical device component manufacturing, CES Machine is a trusted partner for companies seeking customized medical trocar parts that meet regulatory, functional, and performance requirements. Whether you need a prototype or full-scale production, we collaborate closely with your team to develop high-precision, reliable solutions tailored to your needs.

Ready to discuss your trocar component project? Contact us today to learn more about how CES can deliver precision-engineered parts for your medical applications.