ITAR Regulations in CNC Machining

Why ITAR Regulations Matter in CNC Machining: How CES Machine Ensures Compliance & Precision

In the world of precision manufacturing, compliance with ITAR regulations is not just a requirement—it’s a necessity. For companies operating in the aerospace, defense, and military sectors, ensuring that sensitive components are manufactured securely and in compliance with U.S. laws is critical.

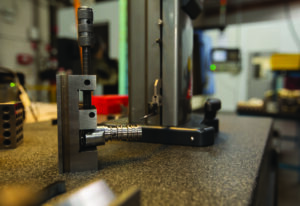

At CES Machine, we understand the importance of International Traffic in Arms Regulations (ITAR) and CNC machining, and we take every measure to maintain the highest level of compliance. Whether you’re producing high-precision parts for defense applications or aerospace systems, partnering with an ITAR-compliant CNC machine shop like CES ensures your project meets all regulatory standards while maintaining precision and confidentiality.

What Are ITAR Regulations?

International Traffic in Arms Regulations (ITAR) is a set of U.S. government rules that control the export and import of defense-related articles and services. Administered by the U.S. Department of State, these regulations aim to prevent unauthorized access to sensitive military and defense technologies, protecting national security interests.

For CNC machining companies that manufacture components used in military aircraft, weapons systems, satellites, and defense-related equipment, ITAR compliance is mandatory. Any company handling controlled technical data or manufacturing parts listed on the United States Munitions List (USML) must follow strict guidelines to ensure that no foreign entities gain access to critical defense information.

Failure to comply with ITAR can result in severe penalties, including fines, loss of contracts, and even criminal charges. That’s why choosing an ITAR-registered CNC machining provider is essential when producing parts for defense applications.

Why ITAR Regulations Matter in CNC Machining

ITAR regulations play a crucial role in CNC machining, particularly when manufacturing parts for aerospace, military, and defense industries. Here’s why compliance is so important:

1. Protection of Sensitive Information

ITAR ensures that technical data and designs for defense-related parts do not fall into the wrong hands. CNC machining facilities that comply with ITAR must have strict security protocols in place to protect customer data, including secure file transfers, access controls, and facility restrictions.

2. High Standards of Manufacturing Precision

Defense and aerospace applications require extreme precision. ITAR-compliant machine shops like CES Machine follow rigorous quality control measures, ensuring that every component meets exact specifications without deviations that could compromise safety and functionality.

3. Legal and Contractual Compliance

Companies working with Department of Defense (DoD) contractors, aerospace manufacturers, and government agencies must adhere to ITAR regulations to maintain eligibility for contracts and partnerships. Non-compliance can result in severe consequences, including loss of business opportunities.

4. Supply Chain Security & Trust

By working with an ITAR-compliant CNC machine shop, businesses can confidently source critical parts from a trusted manufacturer that meets all security and compliance requirements. This reduces risks in the supply chain and ensures that defense-related projects remain confidential and secure.

How CES Machine Ensures ITAR Compliance & Precision in CNC Machining

At CES, we take ITAR regulations seriously. Our facility and operations are designed to meet or exceed all ITAR compliance requirements, ensuring that our customers can trust us with their most sensitive aerospace and defense machining projects. We prioritize data security, regulatory adherence, and high-precision manufacturing, allowing us to deliver components that meet the strictest industry standards while safeguarding classified technical information. Our commitment to compliance ensures that our partners remain legally protected and that their projects are handled with utmost confidentiality and security.

To uphold these high standards, CES implements a comprehensive approach to ITAR compliance that includes strict security protocols, advanced CNC machining capabilities, and rigorous quality control measures. As an ITAR-registered facility, we maintain full U.S. State Department registration, follow secure data handling practices, and limit access to ITAR-controlled projects. Our CNC machining and Swiss turning capabilities enable us to produce high-precision parts for defense and aerospace applications, while our adherence to AS9100 and ISO 13485 quality standards ensures consistency and reliability.

If you require ITAR-compliant CNC machining services, trust CES to deliver precision, security, and compliance for your most critical projects.

Contact us today to discuss your ITAR-regulated machining needs and learn how we can support your defense and aerospace manufacturing requirements.